The CICLO Transmissions project focuses on developing technological solutions for recycling and recovering composite materials that are used to build wind turbines.

Currently, 83% of the materials that make up a wind turbine can be recycled or reused. However, blades are extremely challenging because of their heterogeneous composition and the fact that they contain materials that are difficult to treat and separate properly using conventional recycling processes. The CICLO project (2025-2028) has been created with the aim of providing a solution to this challenge. Eight companies and six research centres are taking part in this project, including the GAIKER Technology Centre, which is a member of the Basque Research & Technology Alliance (BRTA), and coordinator of the AEI consortium.

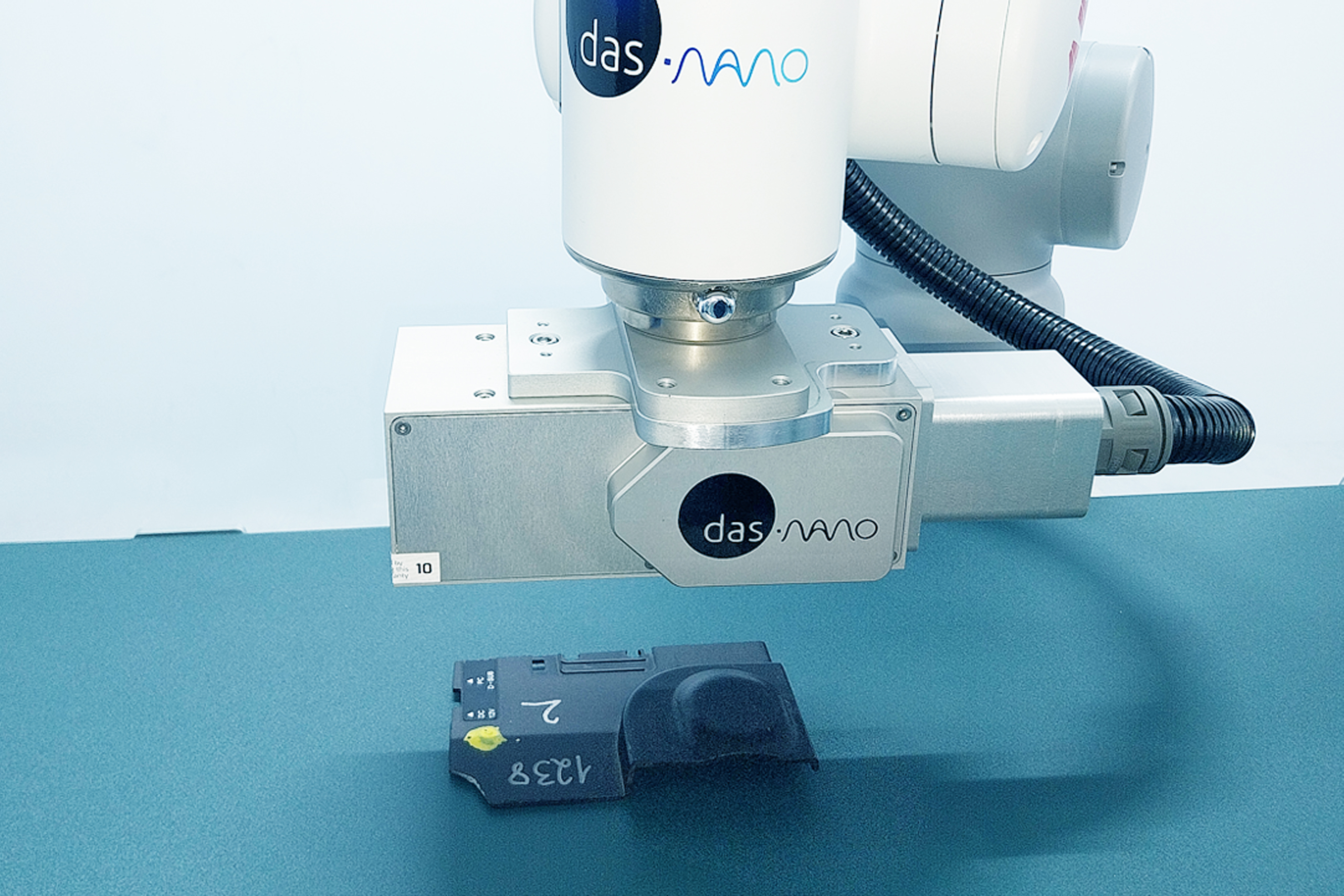

The main goal of this project is to conduct research into new technological solutions to boost the circular economy in the field of renewable energy, specifically for recycling and recovering blades and other composite components used to build wind turbines, such as nacelles, electrical cabinets, etc. at the end of their life cycle. In addition, research will be carried out into the development of alternative materials that are easier to recycle compared to existing materials, in the form of recyclable polymer matrices.

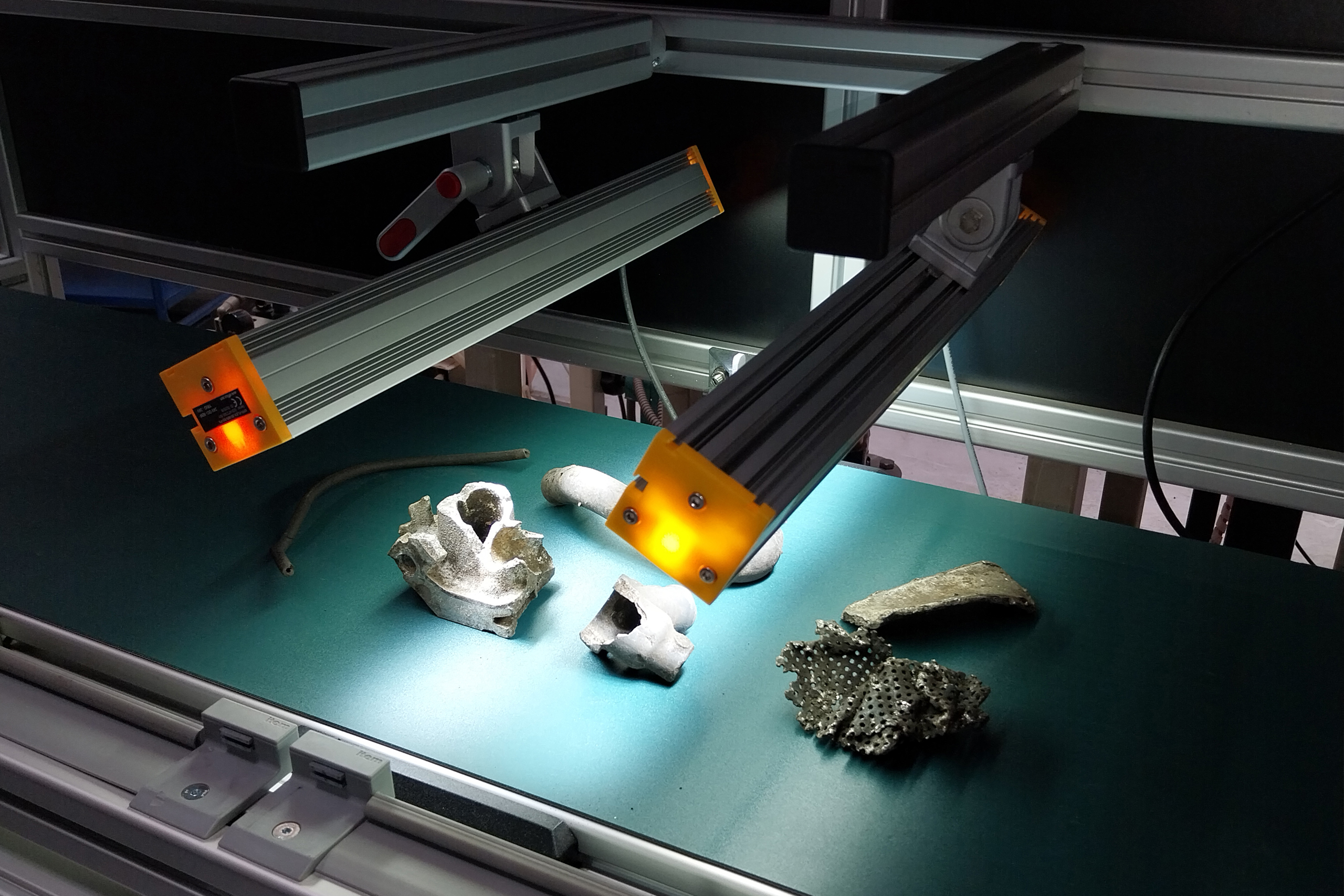

The project aims to optimise the recovery of fibres and by-products from thermal and chemical recycling, so that at least 90% of the recycled fibre is recoverable and the efficiency in the recovery of by-products from recycling exceeds 75%. It also aims to reduce the formation of organic pollutants in thermal processes by 50% and to improve the enzymatic degradation of epoxy resin, polyester and polyurethane. These developments will strengthen the sustainability and efficiency of composite recycling and promote the creation of second-generation structural materials with a 100% recycled content, integrating high percentages of recycled fibres.

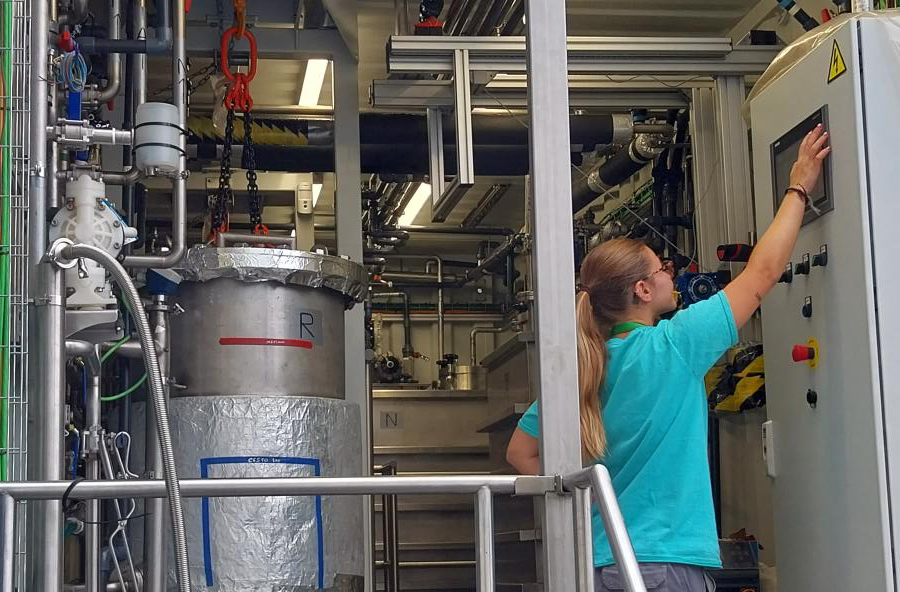

GAIKER, as an expert in sustainable composites and recycling and circular economy, is coordinating the project’s AEI consortium, and will be in charge of researching technologies for remodelling, joining and functionalising fibre-reinforced composite plates extracted from the blade for new applications. It will also explore chemical recycling processes to recover reinforcement fibres and polymer matrices, including recycled reinforcement fibres in BMC and SMC intermediate products and seeking alternative material recovery of liquids from such recycling for the formulation of new resins. Research will also be carried out into the recovery of lightweight blade components (foams and balsa wood) by developing a new generation of lightweight cores and new recyclable and sustainable high-performance composites, using infusion technology, which also incorporate recovered fibre and lightweight cores.

Subsidised by the Centre for the Development of Industrial Technology (CDTI by its Spanish acronym) and backed by the Ministry of Science and Innovation within the Transmissions 2024 Programme (PLEC2024-011215), CICLO, using an integrated approach that includes separation, extraction, recycling, formulation and processing, aiming to recover practically 100% of composite materials.

Project PLEC2024-011215 funded by MICIU/AEI/10.13039/501100011033 and by ERDF, EU.