Article written by Rafael Miguel – Recycling and Circular Economy Market Manager at GAIKER – See original

Europe is facing a major problem regarding its dependence on key raw materials, as its economies are highly exposed geopolitically, thereby posing a serious risk to the continent's security, autonomy and economic viability.

The availability of certain key minerals and the ability to process them is becoming a key issue in areas such as energy transition and other important sectors such as electronics, energy, industry, aeronautics and the automotive industry. These minerals are essential for manufacturing batteries, solar panels, wind turbines and other technological products and it is estimated that there will be a 20% shortfall in supply to meet global demand by 2035.

In view of this expected increase in demand in the coming years and in order to reduce its heavy dependence on foreign sources, the European Union approved new regulations on Critical Raw Materials in March 2024. The aim is to ensure a more stable and diverse supply of these minerals, encourage recycling, and support research into using them more efficiently and finding alternatives.

GAIKER is committed to supporting companies in the transition towards a circular economy, and has taken a holistic approach towards recycling, recovering and valorising essential mineral resources, by optimising recycling techniques, improving the efficiency of recovery processes and exploring new ways to valorise materials.

Among its most notable achievements, the Technology Centre has developed advanced processes for recovering valuable minerals from various types of industrial and post-consumer waste, such as waste from electrical and electronic equipment (WEEE) and end-of-life vehicles (ELVs). An example of this is its participation in the CIRIAMET project – smart technologies to promote the circularity of metals in the new generation of end-of-life vehicles (ELKARTEK Programme run by the Basque Government, 2024–2025).

The Centre also has experience in developing and optimising hydrometallurgical processes aimed at recovering strategic raw materials and high added-value metals. It uses its in-depth knowledge of leaching, separation and purification technologies to design and tailor solutions that make it possible to extract critical metals from industrial and electronic waste and secondary streams, helping to drive the circular economy and reduce dependence on primary raw materials.

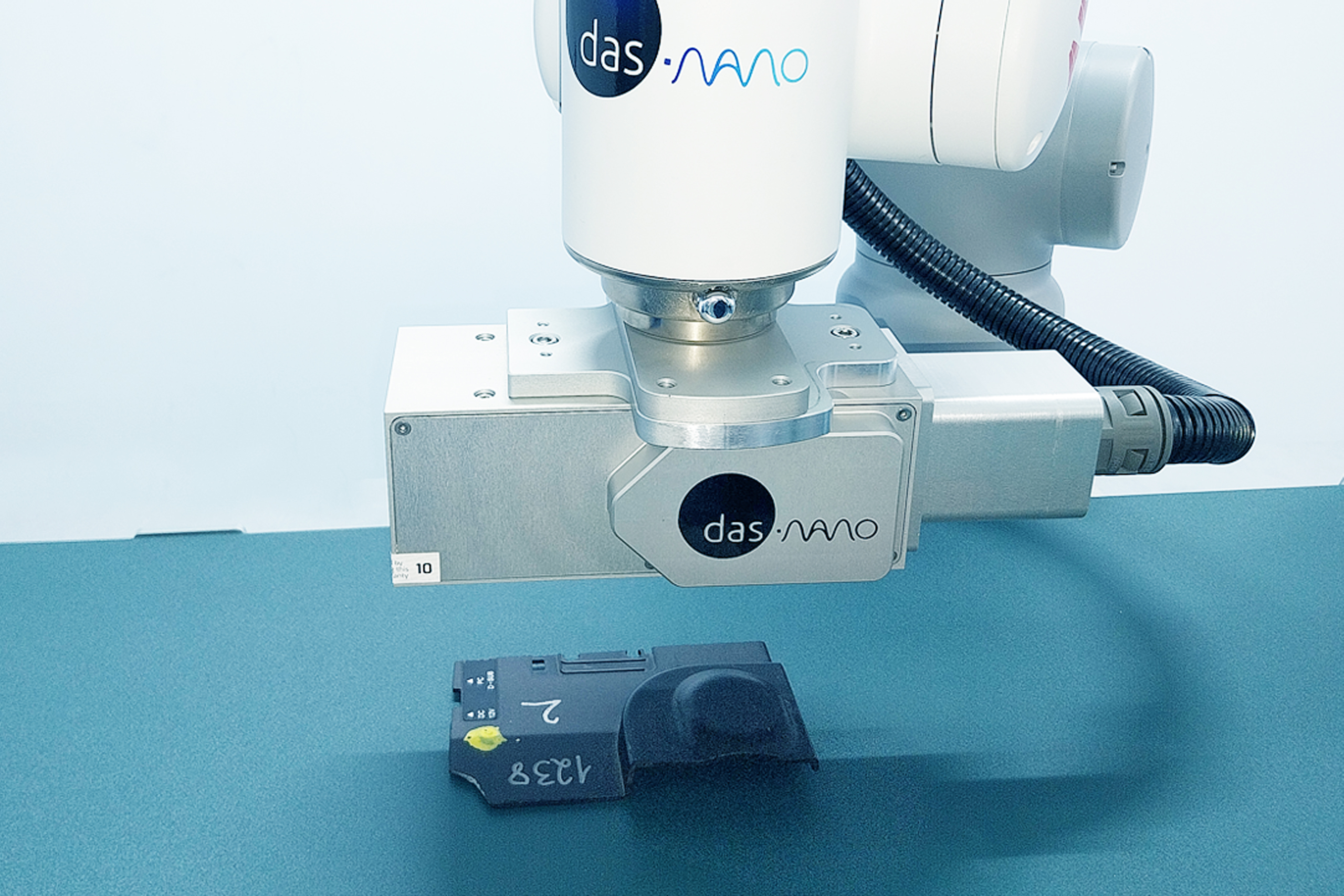

Moreover, GAIKER has a wide range of equipment for both separating and classifying materials using physical and mechanical processes. It has analytical equipment and advanced real-time identification systems and software tools to pre-process signals and train and validate AI-based predictive identification models.

Its multidisciplinary team combines advanced capabilities and laboratory- and pilot-scale experimentation and process simulation, enabling it to tackle R&D and technology transfer projects across the entire hydrometallurgical recovery value chain. Its areas of expertise include developing selective leaching systems using conventional and alternative chemical agents, applying precipitation, ion exchange and solvent extraction technologies, and the integral recovery of the resulting liquid and solid streams.

Likewise, GAIKER is actively working on research into more sustainable and environmentally friendly processes, incorporating less aggressive reagents. These capabilities have put the Centre in the privileged position of collaborating with companies and administrations to design and implement innovative processes aimed at recovering strategic metals such as cobalt, nickel, lithium, rare earth elements and other essential elements for the technology, energy and electric mobility sectors.